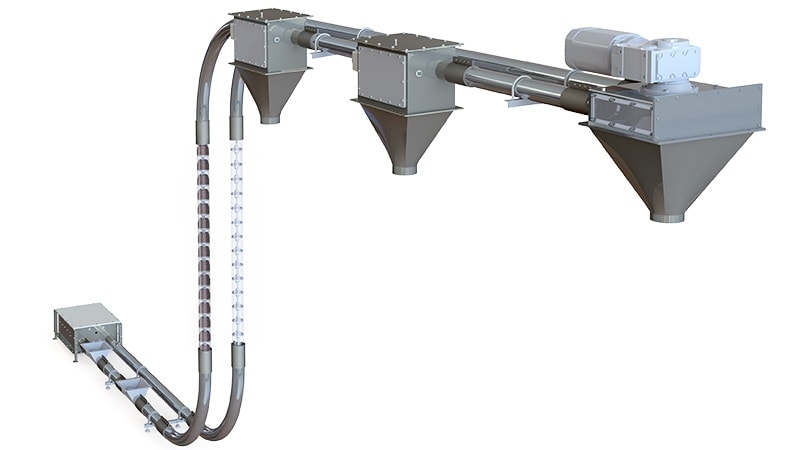

Chain-Vey offers equipment for transporting products using discs and chains. The tubular conveyors are efficient, food-safe, low-maintenance, flexible, and can incorporate a cleaning system.

It is the ideal type of transport for delicate products that need to maintain their structure, as it moves them gently. This ensures a high-quality final product.

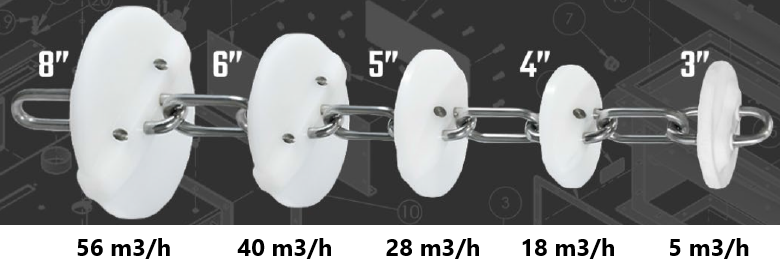

The systems can be found in different sizes, depending on the target capacity sought, and the wide variety of available diameters allows us to adjust very precisely to the requirement.

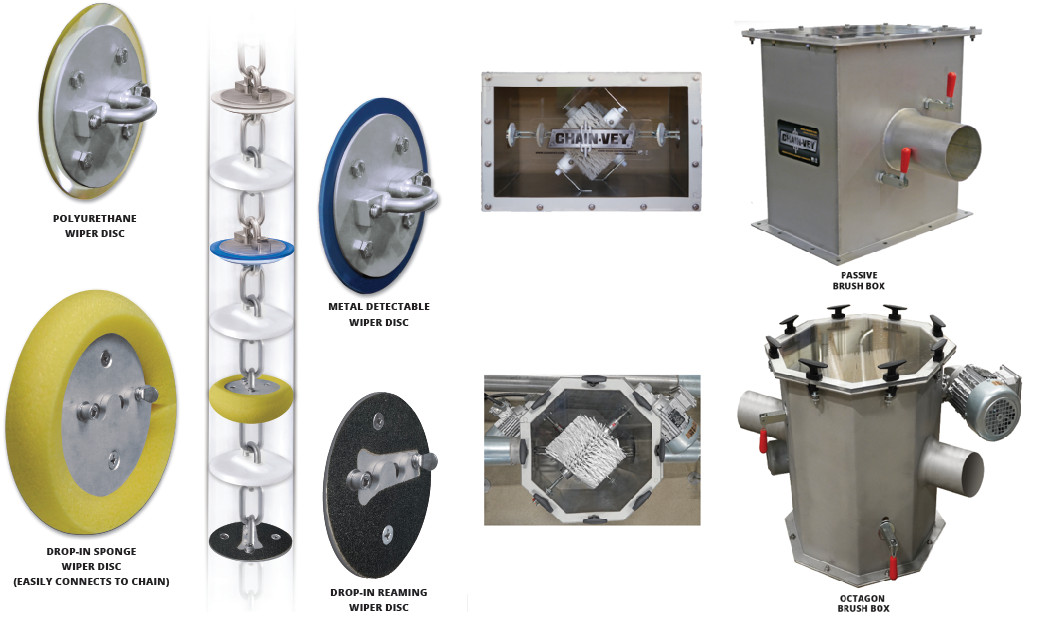

These systems offer the possibility of incorporating various cleaning systems, both dry and wet, which helps save a significant amount of downtime and labor.

- For dry cleaning: polyurethane discs, sponges, abrasive and/or metal-detectable discs, passive and/or motorized cleaning brushes.

- For wet cleaning, we offer CIP systems of different grades.

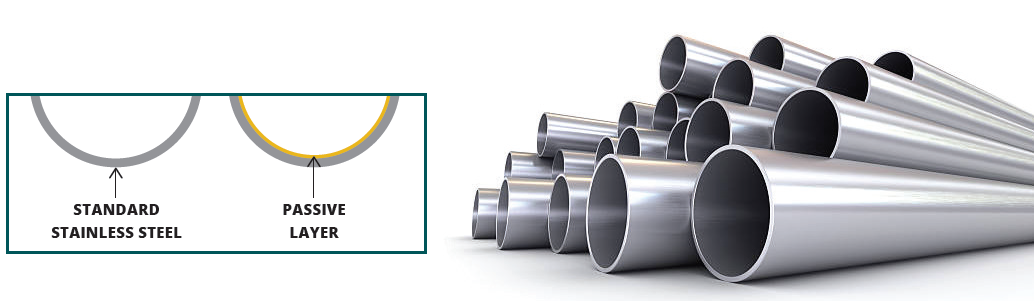

Additionally, certain greasy or oily products tend to react with the iron present in carbon steel or even with the iron found in stainless steel. For this reason, it is possible to pigment the internal wall of the tubes with an acid film, which creates a passivation layer on the material, providing a non-reactive surface for the product. This ensures the transported product retains its integrity and original color, without undergoing alterations.

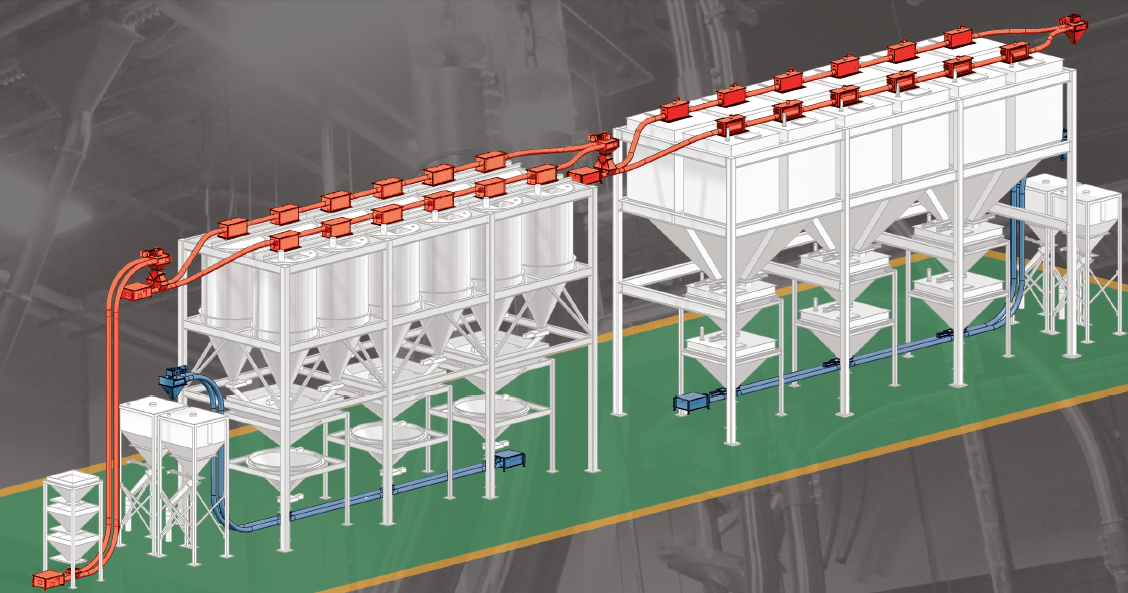

The system is capable of reversing its rotation direction, making it highly efficient when filling a large set of silos positioned in two rows. This means simply pressing a button, and the system reverses its rotation by 180°.

All our tubular conveyor systems are robust, hygienic, gentle, and quiet. The durable, low-friction discs are designed to reduce maintenance costs and energy consumption.

It is possible to perform an internal visual inspection of the system thanks to its easily attachable integrated camera. This allows you to check the system's cleanliness and prevent potential issues. The study results will appear as follows:

Assembling the system is very simple and quick. Even joining the chain takes no more than a minute. Thanks to the polyurethane disc, we guarantee two functions: a perfect link between the chain segments and continuous cleaning of the internal walls of the tubes.

If you would like to learn more details about the Chain-Vey system, we invite you to watch the following video: